Electronic Connection Management System

For the installation and documentation of electrical busbar systems and switchgears

- Assembly documentation

- Projekt controlling

- Commissioning protocols

- Offline mode

- Task and schedule planning

- Document management

- Tool and measuring device management

- Legal protection and data security

From paperwork to digital assembly documentation

Digitisation and increased efficiency of your documentation process.

Let's digitise and increase efficiency

From paperwork to digital documentation with ECMS

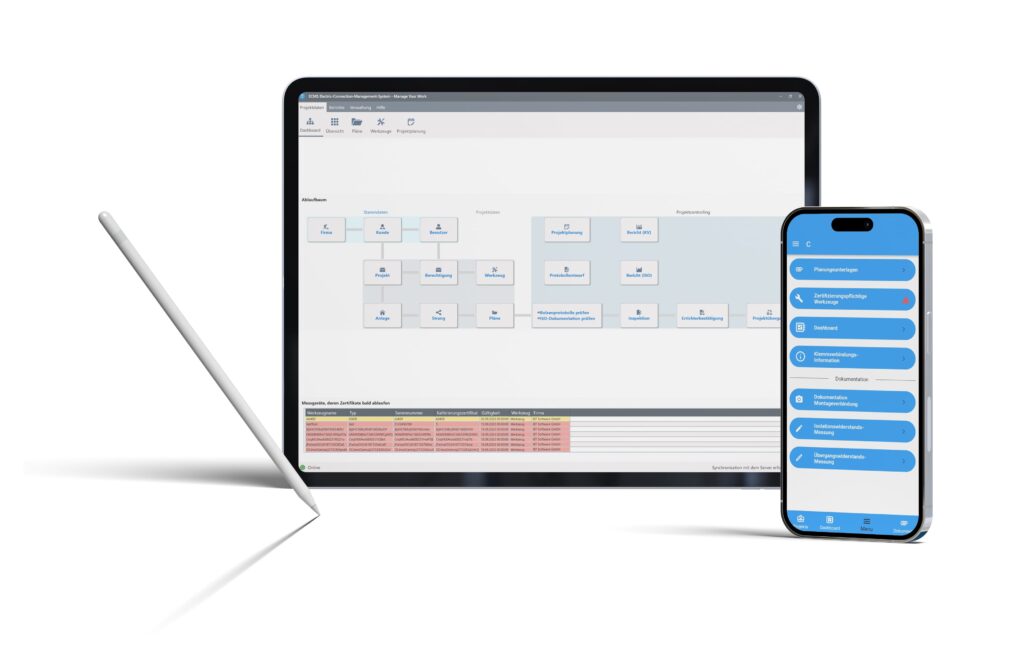

The idea behind ECMS is a software solution that supports project managers and fitters during the installation of electrical systems. The previous paper-based system, characterised by folders and handwritten logs, has been replaced by a digital solution. Project managers can now view and coordinate all project data from their computer or tablet, while fitters on the construction site can use smartphones or tablets to access the necessary documents and document progress in real time. This transformation has led to a significant increase in efficiency, reduced error rates and improved collaboration, satisfying both employees and customers.

All the steps required for documentation, from the start of the project to handover to the customer, are presented in a user-friendly way. The user organises, coordinates and monitors the processes and the course of the project.

The documentation progress of your busbar system and switchgear projects is presented in a clear and user-friendly way.

Our app enables employees to create reports, test and measurement protocols. The intuitive process ensures efficient documentation during assembly.

Archiving is automatic and there is no need to file printed documents.

The logs and measured values are analysed using the desktop application. By checking the documentation and providing feedback to the employees, deviations in the project can be recognised and eliminated at an early stage.

All planning documents as well as measurement and photo documentation can be called up, analysed and evaluated at any time.

Completion of the project and simple handover of the project to the client.

Features & Modules

Overview of the ECMS features and modules

Realised projects

CATL battery factory in Arnstadt near Erfurt

Contemporary Amperex Technology Co. Limited is the largest Chinese manufacturer of lithium-ion batteries and the world's largest manufacturer of batteries for electric cars.

FRA18 Data Center Offenbach

An expansion of the Frankfurt data centres to over 8,080 m² to offer more opportunities for growth.

FRA21 & FRA22 Data Center Frankfurt am Main

On a site of over 3 hectares near Frankfurt Airport, an extension of the Frankfurt data centres was built to over 45,000 m² with a critical IT load of 56 MW.

BER21 Data Center Berlin

Just 10 km from Berlin Airport, two data centres, with an area of 24,000 m² and a critical IT load of 32 MW.

HH1 Data Center Hamburg

The data centre in Hamburg 1 has an area of more than 1,100 m² and an IT load of around 0.8 MW.

The Electronic Connection Management System has piqued your interest?

Get started now with ECMS and take your company to a new level of efficiency!

Contact us today and let our experts provide you with professional advice.

Your advantages with ECMS - Electronic Connection Management System:

- Assembly documentation

- Projekt controlling

- Commissioning protocols

- Offline mode

- Task and schedule planning

- Document management

- Tool and measuring device management

- Legal protection and data security